280,000 new cars were registered last month, compared with 254,000 in March 2020 – that puts registrations of the new 21 plate up 10% on the same time last year. It’s significant because, the motor industry, in common with our own sector, has had to adapt to a new sales format with showrooms remaining closed throughout the last month.

It also shows that consumers continue to feel flush. The Bank of England Monetary Policy Committee suggests that this runs to the tune of £125billion. Consumer confidence remains high, and housing mortgage approvals are up by more than 40%.

The extension of the stamp duty holiday to June, meanwhile, continues to drive activity in the housing market.

Activity in the housing market, cash in their wallets (and let’s face it, still very little else to spend it on!), continues to drive the boom in home improvement.

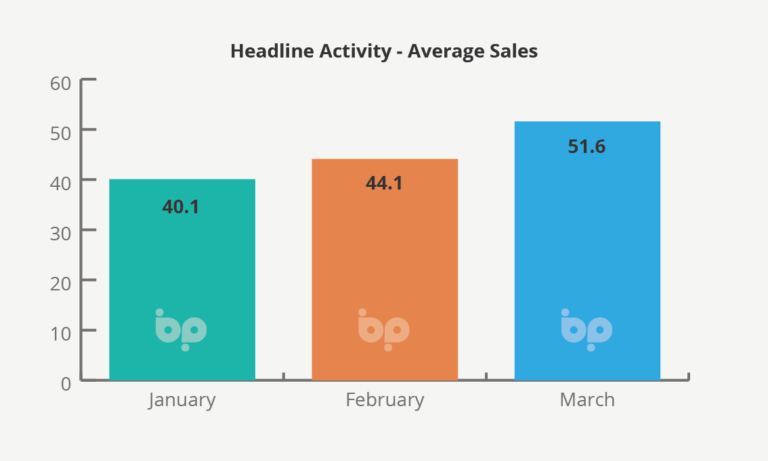

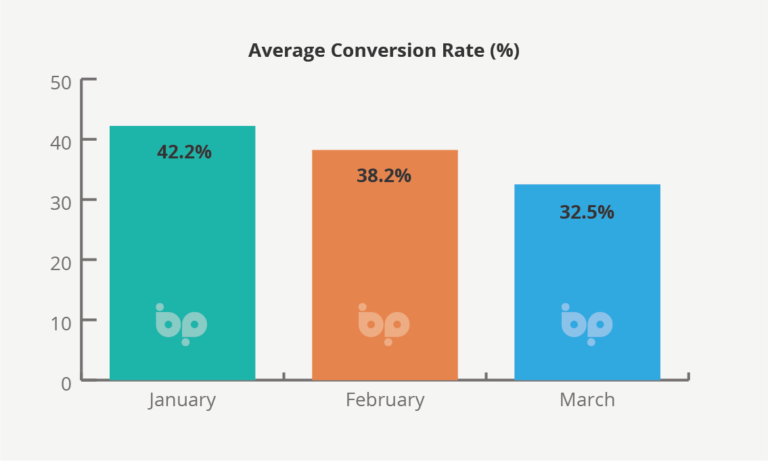

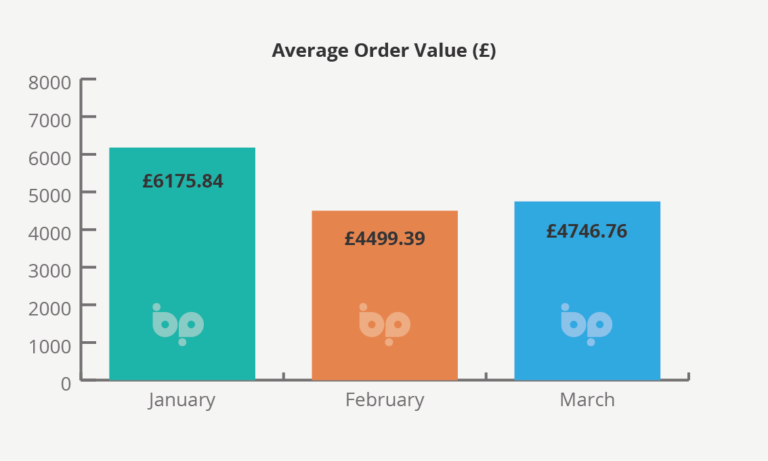

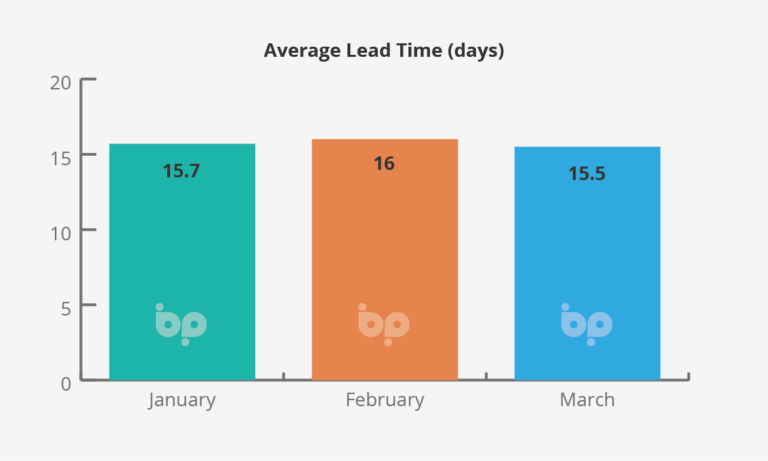

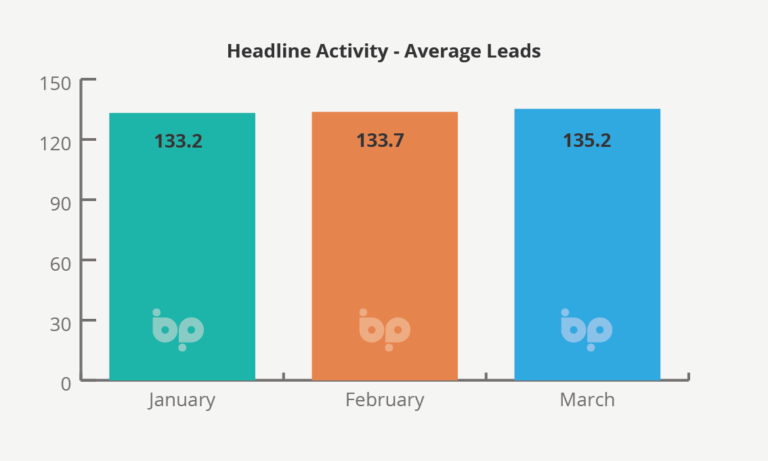

This translated into an increase in sales March on February of 17%. Average order value was up 6% at just short of £4,750 and leads were up also slightly up. Conversation rates were, slightly down at 32.5%, something which we’ll need to track next month but overall the figures paint a positive picture.

The comparison is in a sense not a fair one but compared to March 2020, when demand fell off a cliff edge, in March this year the market is up 18% year-on-year, significantly outstripping growth in the car industry.

And like the car industry we are also facing challenges in supply. Covid-driven disruption has left car makers struggling to source computer chips. Our own problems may be a little less high tech but with polymer suppliers calling force majeure on resin; composite slabs and hardware delayed, as well as disruption in glass supply, they are not insignificant.

While price increases may be difficult to swallow, not having the product to make or supply, is an altogether more bitter prospect.

This is something which is going to make managing your installations, your supply chain, and ultimately your cashflow, in the coming months, critical.

Business Pilot can’t solve all of your supply chain problems but it can help you to manage them more effectively and make it less likely that they impact on your business.

As a starter it will show up your scheduled installations in a different colour dependent on the status of your delivery, either ordered, confirmed delivery date or delivered. It also tracks invoices and assigns them against the job to provide an automatic match, and if it’s outside your projected costs to flag it for follow up.

It simplifies staying on top of your orders so you know that you’ve got the product to go and fit but also allows you to communicate better with your supplier, so you if you do have a problem, for example, something has been delayed, you’ll know and you can manage it.

Cash, as they say is king, and at a time when demand is high, losing track of cashflow, process and profitability, presents an even greater risk.